Principle And Characteristics Of MBBR

Shirley Fu

1. Principle of MBBR process

The principle of the MBBR process is to increase the biomass and biological species in the reactor by adding a certain amount of suspended carrier, so as to improve the efficiency of the reactor. Because the packing density is close to that of water, it is completely mixed with water when aerating. The environment of microorganism growth is gas, liquid and solid. The collision and shearing of carriers in water make the air bubble smaller and increase the utilization ratio of oxygen. In addition, each carrier has a different type of organism inside and outside, with some anaerobic or facultative bacteria growing inside and good bacteria growing outside, so that each carrier is a Microreactor, allowing both nitrification and Denitrification to occur, thus improving the processing effect.

The MBBR process has the advantages of both the traditional fluidized bed and the biological contact oxidation process. It is a new and highly efficient sewage treatment method, then the suspended activated sludge and attached biofilm are formed, which makes the moving bed biofilm use the whole space of the reactor and make full use of the advantages of both the attached phase and the suspended phase, making it develop its advantages and avoid its disadvantages, complement each other. Unlike previous fillers, suspended carriers are called “Moving biofilms” for their ability to make frequent and repeated contact with wastewater.

2. Advantages of MBBR

Compared with activated sludge biofilm and fixed carrier biofilm process, MBBR has the advantages of high efficiency and flexibility of operation, long sludge retention time, and less excess sludge, as well as impact load resistance of traditional biofilm process.

MBBR04

MBBR05

MBBR06

MBBR19

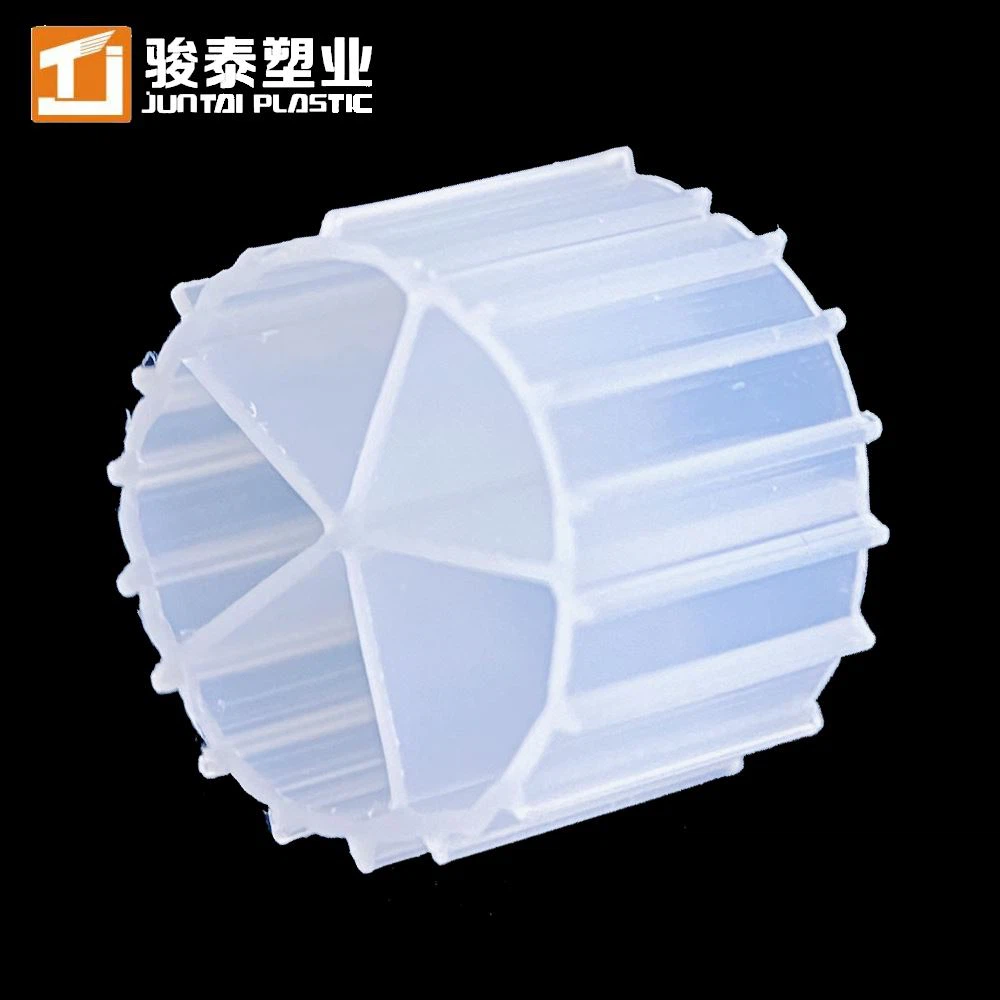

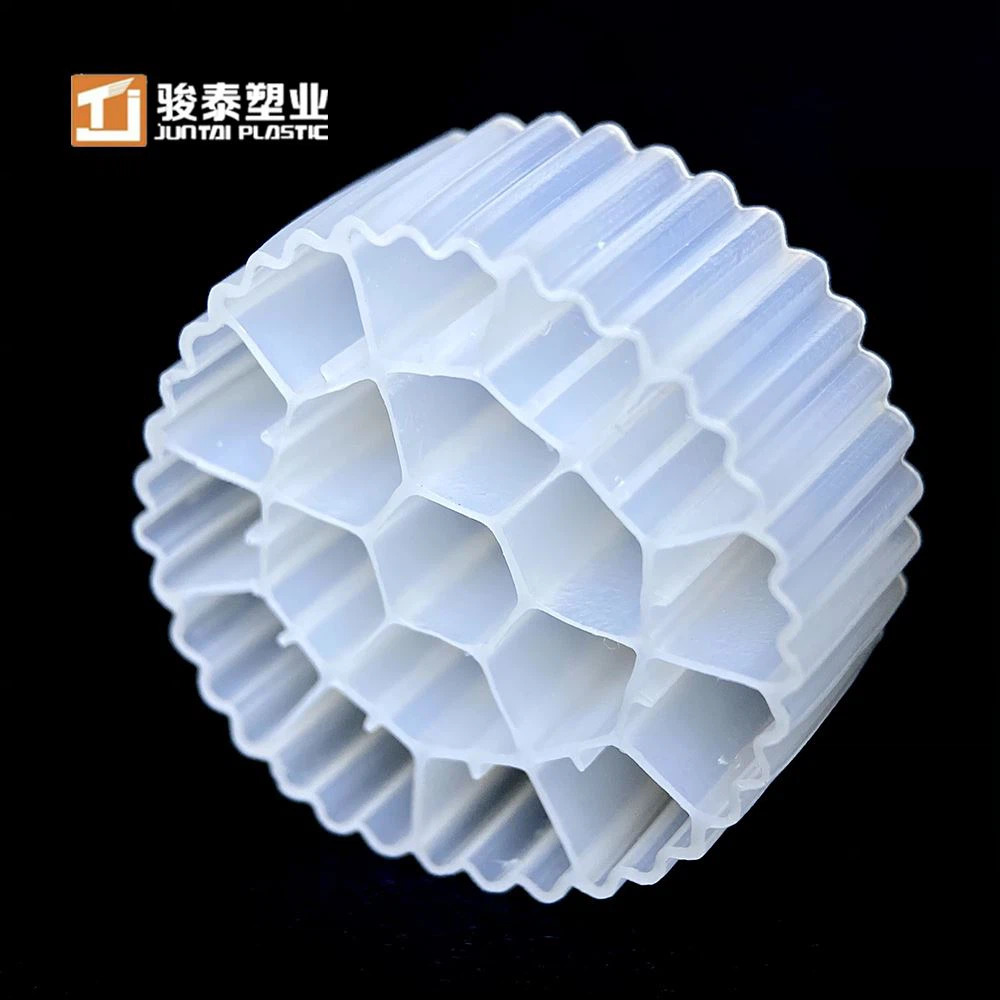

(1) Packing characteristics

The fillers are mostly made of polyethylene, polypropylene, and its modified materials, polyurethane foam, etc. . The specific gravity is close to water, mainly cylindrical and spherical.

(2) Good denitrogenation ability

Nitrification and Denitrification can take place in a reactor, which has a good effect on the removal of ammonia nitrogen.

(3) Removal of organic matter is effective

The concentration of sludge in the reactor is high. The concentration of sludge in the reactor is 5 ~ 10 times that in the activated sludge reactor and can reach 30 ~ 40 g/L. The treatment efficiency of organic matter is improved, and the shock load resistance is strong.

(4) Easy to maintain and manage

There is no need to set up the packing bracket in the aeration tank, which is convenient for the maintenance of the packing and the aeration device at the bottom of the tank and can save the investment and the area occupied.

![]() Hangzhou Juntai Plastic

Products Co., Ltd

Hangzhou Juntai Plastic

Products Co., Ltd

Address:#907, 1 Building XIC, Hangzhou, Zhejiang China