At present, there is no formal national or industry standard for reference on the design and calculation of MBBR process in sewage treatment plants.

The third edition of "Water Supply and Drainage Design Manual" Volume 5 gives the corresponding parameters

(1) The MBBR reaction tank is designed with no less than 2 cells.

(2) Filling volume is calculated based on volume load and average daily sewage volume.

For domestic sewage or municipal sewage dominated by domestic sewage, the MBBR volume load can be 1.0~1.4kgBOD5/(m3·d).

(3) For the purpose of carbon removal only, high load can be considered. When there is a subsequent nitrification step, a low load should be used:

When the load is high (75~80% BOD removal rate), the BOD load per unit surface of the carrier may be> 20g/ (M2·d)

Under normal load (80~90% BOD removal rate), the unit surface BOD load of the carrier can be 5~15g/(m2·d)

Under low load (before nitrification), the unit surface BOD load can be 5g /(M2·d).

(4) When used for denitrification

The pre-denitrification rate is generally 0.15~1.0g/(m2·d),

The post-denitrification, when the carbon source is added excessively, the maximum nitrate carrier surface area removal rate of the external carbon source Can be greater than 2g/(m2·d).

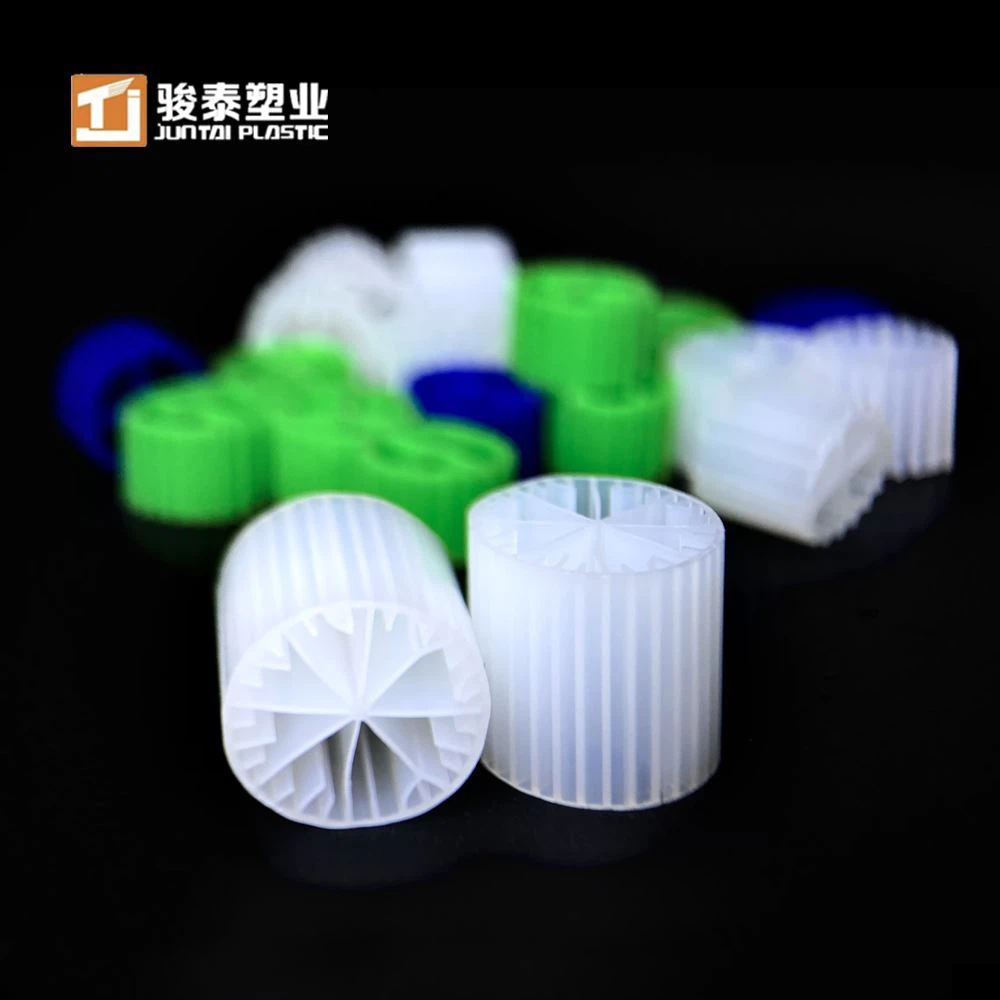

(5) The specific surface area of the selected filler is generally 200~600m2/m3, and the filling ratio is generally 35%~60%.

(6) Generally, the peak flow velocity is not more than 35m/h, otherwise the packing will accumulate.

(7) The HRT of hypoxic MBBR is generally 1.0~1.2h,

The HRT of aerobic MBBR is generally 3.5~4.5h.

(8) In the denitrification MBBR, the power of the agitator can be calculated based on 25~35W/m3.

If you have interest, please contact Doris

Whatsapp/Wechat: +86 13298186953

Email: doris@juntaiplastic.com